Plate Heat Exchanger – What, Where, Why, When, Who!(5W)

WHAT are Plate Heat Exchangers?

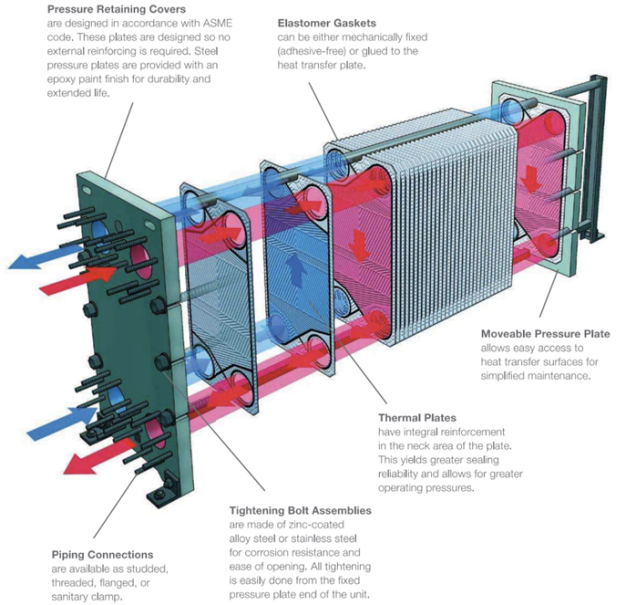

Plate heat exchangers(PHEs) are one of the most common types of heat exchanger employed today. PHEs have gained widespread application throughout the engineering world because they are efficient, robust, and relatively easy to maintain. It is a system engineered to allow heat to transfer between two fluids. These fluids can be in the form of a liquid or gas that are hot or cold in temperature. The careful design of the PHE allows these fluids to pass through separate channels without actually coming into contact with each other, or the heat itself.

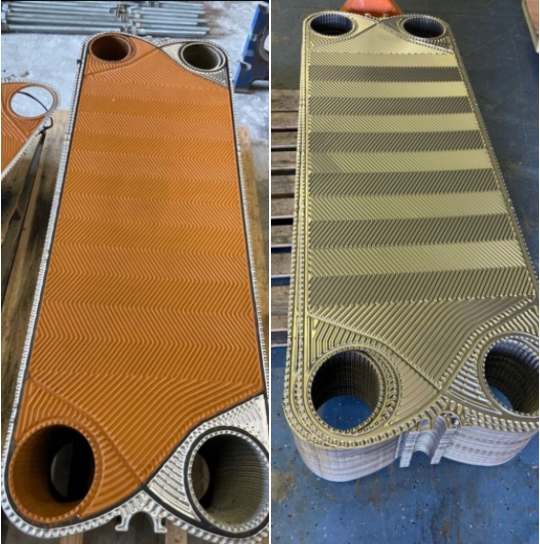

PHEs are constructed using gaskets, corrugated metal, and alloys. The corrugated metal helps make PHEs an efficient and effective way of transferring heat. Here’s an example of what a PHE can look like:

PHEs come in various types and designs, with Jiangyin LJ Service Co., Ltd. providing the following:

· Semi Welded PHE

· Plate heat exchanger

· Brazed Plate heat exchanger

· Gasketed Plate and Frame

· Plates

· Gaskets

· Parts related on PHE

Chat with us to learn more about the different types available, and to determine which PHE will best suit your needs.

WHERE and WHY are Plate Heat Exchangers used?

For these years, LJ Service continues to proudly serve a wide-range of companies across China and all around world that rely on PHEs as a vital piece of their operating equipment. These companies can include food and beverage, brewing, pharmaceutical hygiene, HVAC, power, chemical, water treatment and desalination, mining, oil and gas, milk pasteurization, and marine oil cooler.

Here’s some examples of how industries use PHEs:

· A brewery can use a PHE during the wort and fermentation process of making beer.

· A farm can use a PHE for the pasteurisation process of raw milk. With raw milk passing through one channel of the PHE, and hot water passing through the other channel, any pathogens in the raw milk can be eliminated during this process.

· A mining company can use a PHE for temperature regulation in hydrometallurgical processes, and for water circuits that are used to help keep equipment lubrication systems from overheating.

WHEN do Plate Heat Exchangers need servicing?

Just like cars that need regular servicing, so do PHEs to help keep them operating efficiently. Every PHE will wear out eventually, and maintenance, repair or replacement will be required.

The main culprits of wear and tear on PHEs are fouling, erosion, and corrosion which will reduce the performance of the heat exchanger. PHEs should be serviced every 6 months to 4 years, depending on their environment, with regular maintenance also helping to prevent emergency repairs which could cause costly and unplanned downtime.

You can also contact us if you need repair or clearing service.

WHO can provide quality Plate Heat Exchangers?

As a company who values customers first and foremost, Jiangyin LJ Service Co., Ltd. is a experienced factory in China in Plate Heat Exchanger industry who provides customers with quality PHEs in design and build, services, testing, and equipment and parts.

We’d like to assist you with your Plate Heat Exchanger programs! Please contact us 24/7 365.

Contact our Team:

Telphone: (086) 18861742427

Email: sales@jlheatexchanger.com

Email: barbara@jlheatexchanger.com

Pre:Plate heat exchanger Problem Solving

Next:No more