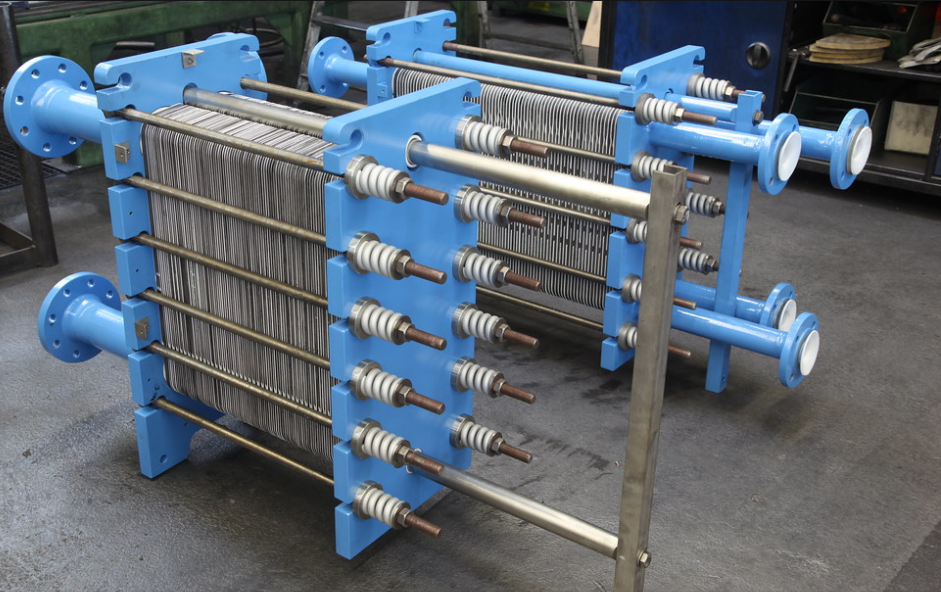

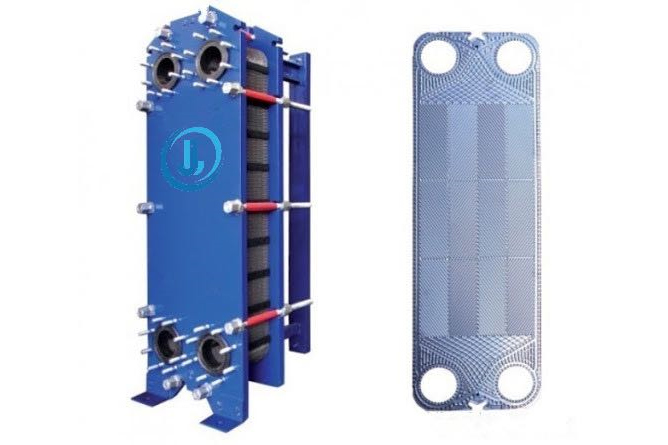

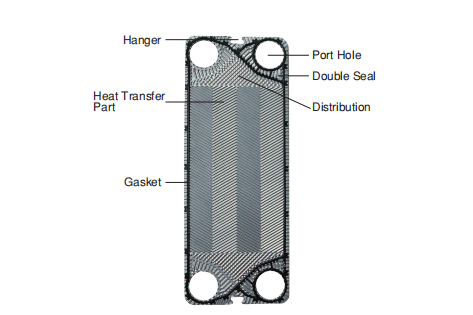

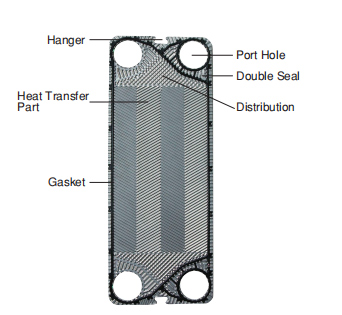

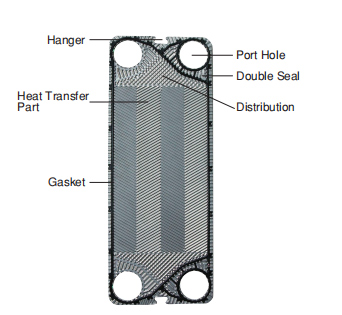

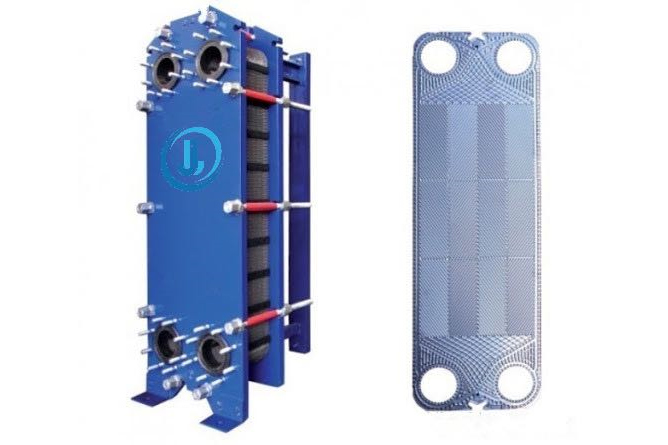

Each heat transfer plate is corrugated to various patterns to increase its strength and heat transfer area. What’s more, the corrugation creates high turbulence and thereby achieve high heat transfer coefficient. The plate is provided with passage hole on each corner. Each plate is tight-sealed with a gasket fitted in its peripheral groove.

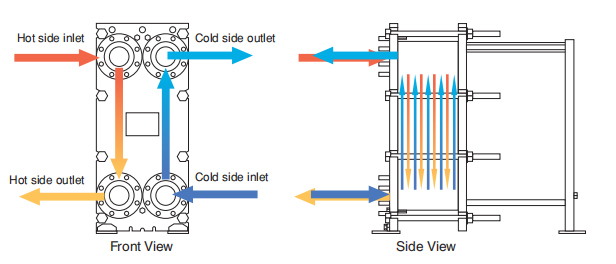

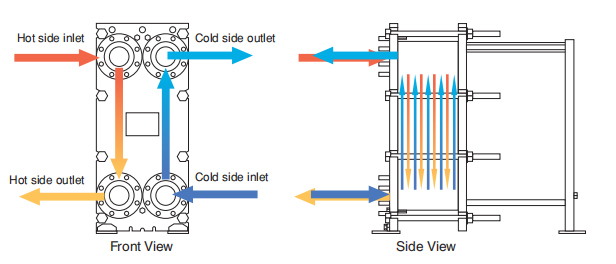

Flow Channel

The plates are divided into A-plate and B-plate, and a passage is formed between these plates. The high temperature fluid flows alternately and in the opposite direction of the other fluid. Thus high efficient transfer of heat is achieved through these plates. A-plate when reversed would become B-plate. As such only one type of plate can be used as A-plate and B-plate for most models..

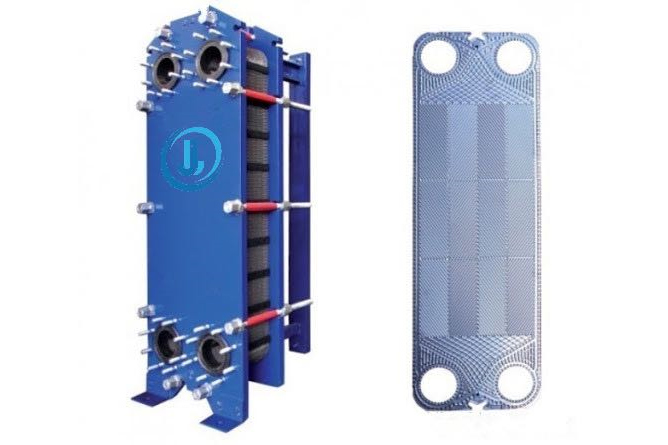

Characteristics of Plate Heat Exchanger

The main features are: high heat transfer coefficient; convenient maintenance and cleaning; low dirt coefficient; compact structure, small footprint, light weight; it is easy to change the heat transfer area or process Combination; small end temperature difference, etc.

PHE Application Areas/Occasions

| Chemical | Coustic Soda, Fertilizer, Petrochemical, Oil Refinery, Oil & Fat, Pharmaceutical, Sulfuric Acid Cooling

|

Food

| Milk, Beer, Soft Drink, Sauce, Wine, Skid mounted Sterilizer

|

HVAC

| Air-Conditioning, Top water heating

|

Steel Mill

| Blast Furnace, Continuous Casting, C.O.G, Plating & Galvanizing, Blast furmace cooling

|

Metal

| Plating, Quenching, Anodizing, Painting

|

Pulp & Paper

| Black Liquor, White Liquor, Digester, Heat Recovery

|

Textile

| Synthetic Fiber, Spinning, Dyeing |

| Central Cooling | Sea Water, River Water, Power Station, Co-generation, Marine and many others. |

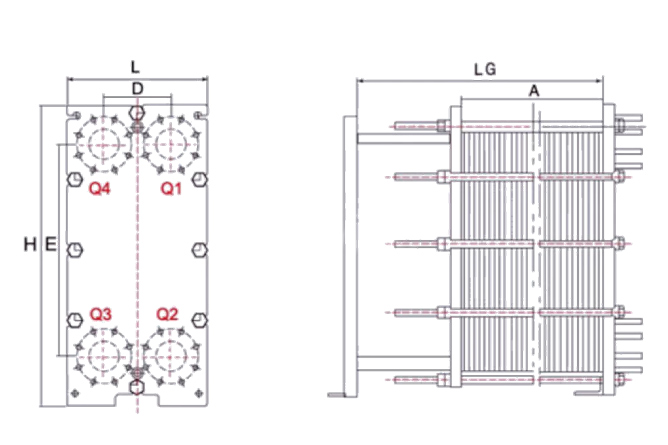

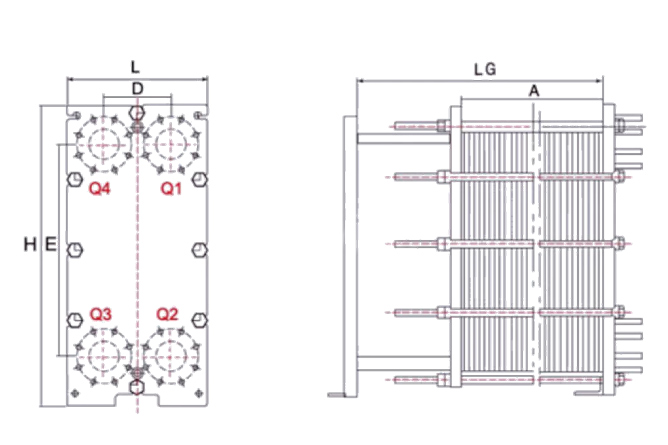

Plate Heat Exchanger Technical Data for Structure

| Frame | Painted fram Stainless steel frame, designed for the food and beverage processing Industry Both frames comes with clamping bolts placed around the frame edge. |

| Design Pressure | Painted frames: 1.0/1.5/2.5 Mpa. (145/217/362 PSI) Stainless steel frame: 1.0/1.6 Mpa (145/232 PSI) |

| Intermediate Frames | Intermediate frames and corner blocks in stainless steel. |

| Connections | DN150/6" flange in carbon steel, rubberlined or cladded with AISI 316 or titanium DN100/4", DN125/5" and DN150/6" dairy unions According to all known standards. |

| Plate Material | AISI304/316, 254 SMO and titanium. Other materials available on request. |

| Gaskets | The gasket is placed in the closed gasket groove, that is formed by the plates. This design makes the plate suitable for high working pressures. The plates are strongly guided during the assembly of the plate heat exchanger. Materials: NBR, EPDM and Viton. Other materials available on request. |

| Extra Equipment | Safety cover in stainless steel Insulating jacket Assembling spanner Foundation feet for common frame Instrument flange Thermometer and manometer |

LJ PHE Specification

| Model | A(mm) | L(mm) | H(mm) | D(mm) | E(mm) | LG(mm) | Size | Maximum size(mm) | Maximum flow(mm) |

| LJ30H | N(2.0+X) | 180 | 480 | 60 | 357 | 400 | 32 | 100 | 10 |

| LJ60B | N(2.0+X) | 320 | 930 | 140 | 640 | 1200 | 50 | 250 | 36 |

| LJ60H | N(3.0+X) | 320 | 930 | 140 | 640 | 1200 | 60 | 203 | 36 |

| LJ60T | N(4.0+X) | 380 | 652 | 203 | 400 | 1200 | 65 | 150 | 50 |

| LJ100B | N(2.5+X) | 470 | 1069 | 225 | 719 | 1600 | 100 | 278 | 140 |

| LJ100H | N(4.0+X) | 470 | 1069 | 225 | 719 | 1600 | 100 | 180 | 140 |

| LJ150B | N(2.5+X) | 610 | 1815 | 298 | 1294 | 3000 | 150 | 600 | 360 |

| LJ150H | N(4.0+X) | 610

| 1815

| 298

| 1294

| 3000

| 150

| 450 | 360 |

| LJ200T | N(4.0+X) | 698 | 1460 | 363 | 740 | 3000

| 200 | 300 | 600 |

| LJ200H | N(4.0+X) | 780 | 2150 | 355 | 1480 | 3000 | 200 | 420 | 600 |

| LJ350 | N(3.5+X) | 1100 | 2415 | 260 | 1720 | 3360 | 350 | 350 | 997 |